Description

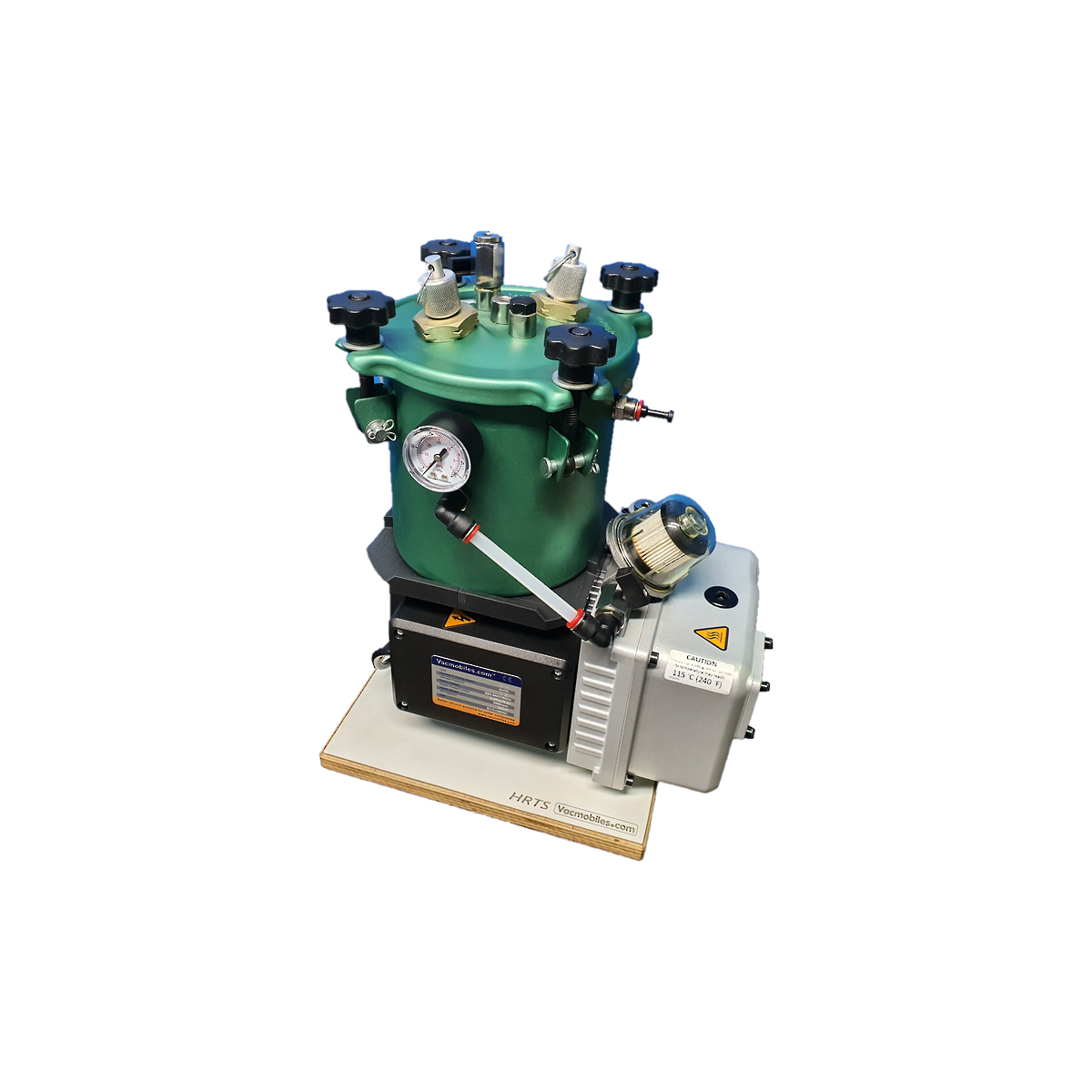

Compact system for infusing or vacuum bagging smaller composite parts.

The Vacmobile HRTS vacuum system is suitable for resin infusing or vacuum bagging small to medium sized parts up to about 5 m² (53.8 ft²) in area, as long as the resin overflow from the part will be less than 950 ml (32 fluid ounces).

While small in size, the HRTS is a continuous duty machine suitable for industrial use, field repairs, training/research and high quality hobby composites. With a noise output of just 60 dB (A), the HRTS is ideal for quiet environments.

The primary uses of the HRTS series are the manufacture of small-sized laminates using resin infusion, vacuum bagging over wet laminate or pre-preg methods. The maximum laminate size that can be infused by an HRTS series machine very much depends on the conditions & experience of the laminator, especially familiarity with the use of wide peel ply resin breaks around the perimeter of the laminate. (For further information on wide peel ply resin breaks, please see our website note Peel ply resin breaks)

Move closer to your work

The HRTS is extremely lightweight and easily moved. This allows the machine to be moved to wherever vacuum is required. The need for inflexible, expensive and leak-prone vacuum distribution pipe work is completely eliminated. Vacuum quality and productivity will both be improved.

Compact & lightweight without sacrificing performance

Although a continuous heavy duty machine, the HRTS has a compact footprint, measuring only 290 mm (L) x 200 mm (W) x 350 mm (H) [11.4” x 7.9” x 13.8”]. It weighs in at just 12.2 kg (27 lbs).

Reviews

There are no reviews yet.