Description

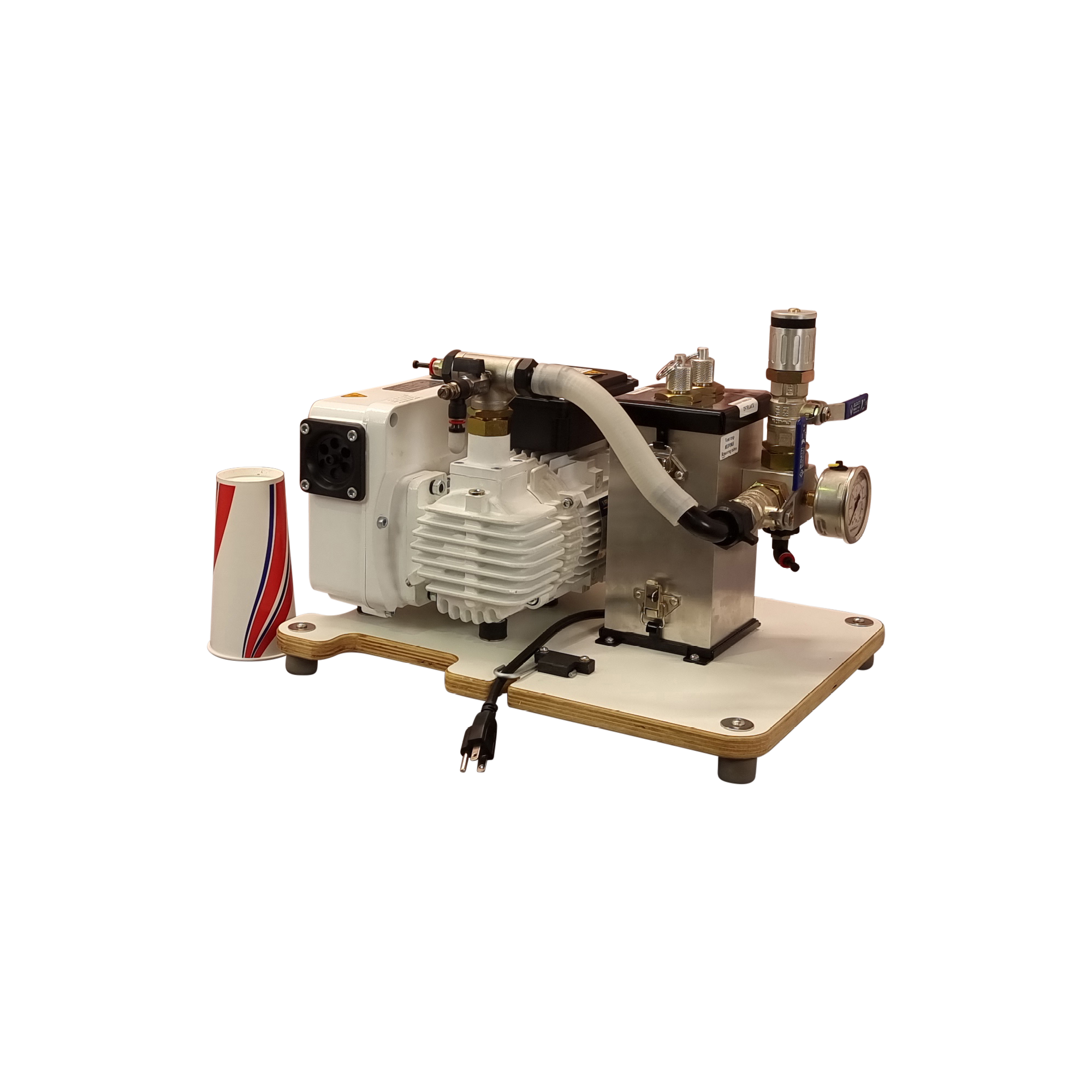

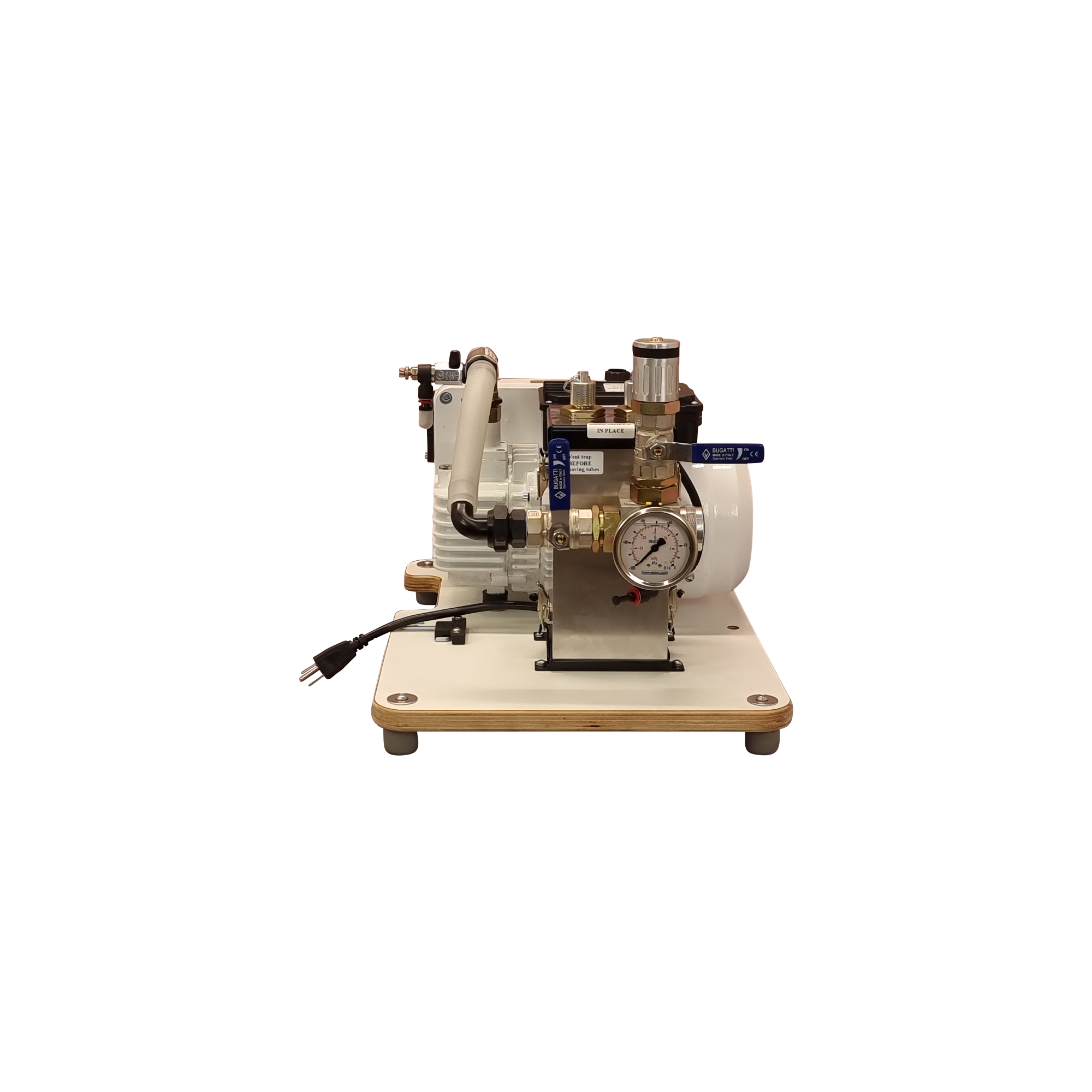

The Vacmobile E1 series is based on a compacted down form of the resin trap from our well proven 20/2 machine. The compact trap uses a standard paper drinking cup as the replaceable resin catchpot. The paper cups supplied with the machine have a resin catching capacity of 600 ml (20 fluid ounces), with similar size cups being available in most countries.

The primary uses of the E1 series are the manufacture of small laminates using resin infusion or moderate sized laminates made by vacuum bagging over wet laminate or pre-preg. The maximum laminate size that can be infused by an E1 series machine very much depends on the experience of the laminator, especially familiarity with the use of wide peel ply resin breaks around the perimeter of the laminate.

As supplied from the factory, an E1 series system is not mobile, but it can easily be added to a customer supplied mobile cart if bench top mounting is not appropriate.

An accessory kit for degassing resin on the way in to the internal catchpot is available as an option. Please see accessory tab.

For more detail on this system, please open the PDF.

Trap Lid Options

Glass lid for infusion Steel Lid for vacuum bagging

Degas Kit

Degas Kit

Reviews

There are no reviews yet.