Description

The original Vacmobile, the 20/2 mobile vacuum system is a proven performer ideally suited to resin infusion or vacuum bagging composite parts, where the resin overflow from the part will be less than 2 litres (4 pints).

Don’t be fooled by its compact size – the 20/2 can successfully resin infuse vacuum bagged products as large as 185 m² (2,000 ft²) when supplemented by a larger (optional) resin trap. The 20/2 arrives ready to run on single phase power, so there’s no costly installation or complicated set up. Exceptionally mobile, the 20/2 allows you to get much closer to your work, where the vacuum is needed the most, which means greater performance and lower operating costs.

The 20/2 vacuum system arrives complete with an integrated resin trap, vacuum gauge, vacuum regulation, coarse particle filter and motor overload protection. It is robustly constructed from proven Vacmobile components, including our unique O-ring sealed trap lid tubing connections, assuring vacuum integrity over a long working life

Very versatile: Single & Dual vacuum levels

The 20/2 has an optional Dual-Vac accessory that seamlessly converts the standard single vacuum level 20/2 into a dual vacuum machine suitable for small RTM Light and double bag infusion processing. This added scope is ideal for laboratories and training facilities where a range of processes need to be demonstrated, or for small manufacturers who are focussed mostly on infusion projects, but occasionally need the ability to undertake Light RTM jobs.

Collapsible for transport

The 20/2’s normal working height of 1065 mm (42″) can be easily reduced to 620 mm (24.4″) making it simple to move between working locations.

Trap Lid Options

Glass lid for infusion Steel Lid for vacuum bagging

Ruggedness proven in more than 60 countries since 2006

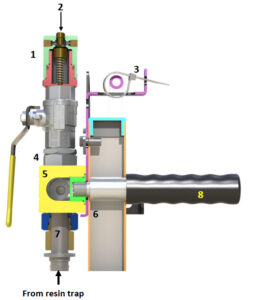

Below: Showing sectional drawing

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- Silenced vacuum regulation valve

- Instant vacuum release button

- Vacuum tubing restraint. Holds tubing from resin trap horizontally or vertically, as required

- Valves mechanically locked to manifold. Cannot loosen or leak

- Manifold machined from solid aluminium block

- Manifold physically locked to main handle of machine. Cannot loosen in service

- O-ring sealed connection to resin trap

- Convenient working height handle and manifold. Can be compacted down for transport

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Glass resin trap lid

Glass resin trap lid Dual-Vac accessory

Dual-Vac accessory Clamping valve kit

Clamping valve kit

Reviews

There are no reviews yet.