It is often helpful to make a transition from one tubing size to another, or to join two similar size pieces into a longer length. If two tubing sizes are compatible, it is possible to make simple, leak tight and low cost size transitions, as described below.

If the smaller tube is a tight fit in the larger tube at ambient temperature

If the smaller tube is normally slightly too large to fit inside the bigger tube by about 0.5 mm to 1 mm (0.02” to 0.04“) use the following method:

- Make sure both tube ends are clean and undamaged and cut neatly square with a tubing cutter (not with scissors or a knife, as these tend to crush the tube).

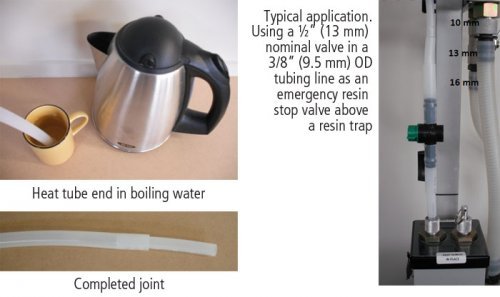

- Boil water in a kettle and pour into a cup until about 50 mm (2”) deep.

- Insert the end of the bigger tube into the freshly boiled water and hold it there for about 5 to 10 seconds.

- Withdraw from the water and immediately press the smaller tube into the softened bigger tube. Aim for at least 10 mm or ½” of insertion but don’t press so hard that the tubes buckle.

- Allow the joint to cool to ambient and test the joint. If difficult to pull apart, the joint should have satisfactory strength and be vacuum tight without need for mastic.

- If any concern about leak tightness, use super glue in the joint, or brush an aerobic liquid pipe sealant around the joint while the tube is under vacuum. This should seal any small leaks.

A hot air gun may be used in place of boiling water, but the results will not be as controllable and there is a risk of heating too much of the tube.

If the smaller tube is a loose fit in the larger tube at ambient temperature

If the Outside Diameter (OD) of the smaller tube is smaller than the Inside Diameter (ID) of the bigger tube, use mastic to join the two tubes. For the strongest mastic joint use the following method:

- Make sure both tube ends are clean and undamaged and cut neatly square with a tubing cutter (not with scissors or a knife, as these tend to crush the tube).

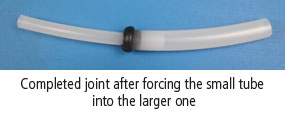

- Apply a ring of mastic around the smaller tube, about 12 mm (1/2”) from the end of the tube. Make sure the mastic forms a complete ring around the tube.

- Force the smaller tube into the larger one. The mastic will roll until it adheres to both tubes. Continue pushing until the joint becomes firm (without buckling the tubes)

- If any doubt about vacuum tightness, apply more mastic to the outside of the joint.

Feedback or queries on this note?

We are keen to improve the accuracy and value of Vacman’s Notes. If you have any feedback or queries regarding this note, or would like to suggest new topics to be covered, Vacman would be pleased to hear from you! Please comment below! Or email [email protected]