Why choose our machines?

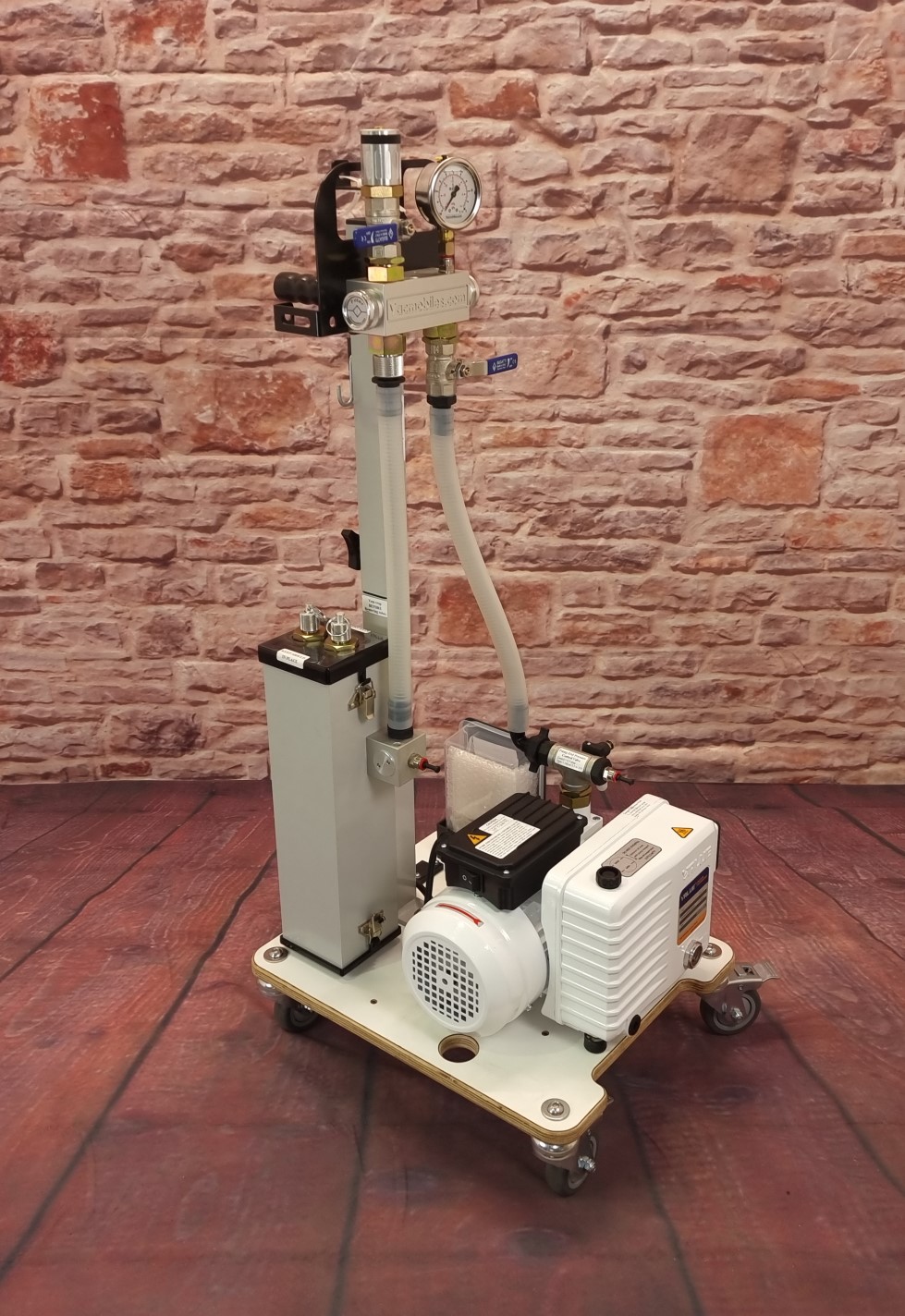

Vacmobiles can be delivering highest quality vacuum for infusion within 60 minutes of unpacking.

Vacuum is proving to be a key element of low to medium volume composites manufacturing processes because it enables high quality manufacture without the considerable capital cost and risk associated with mass production methods.

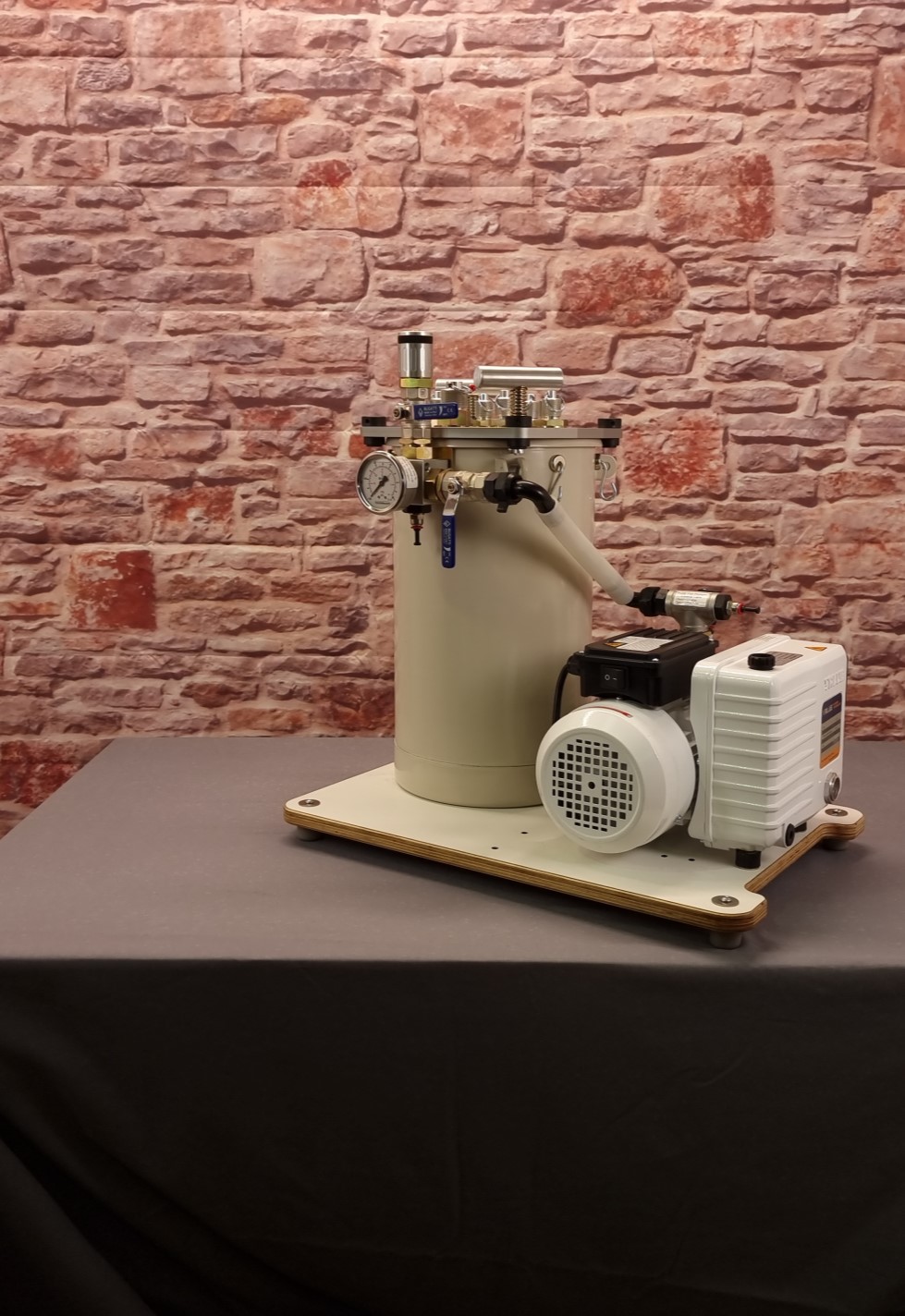

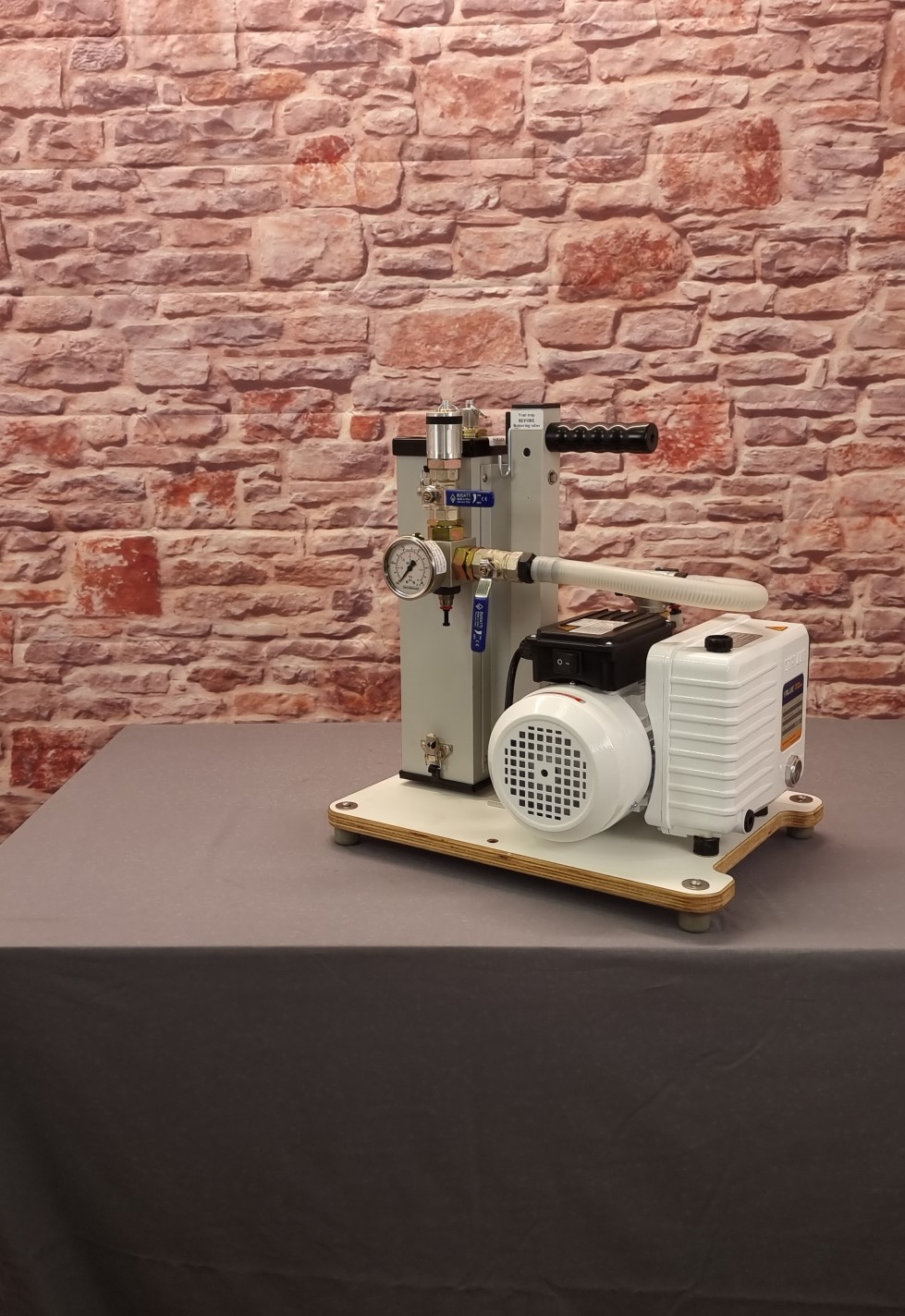

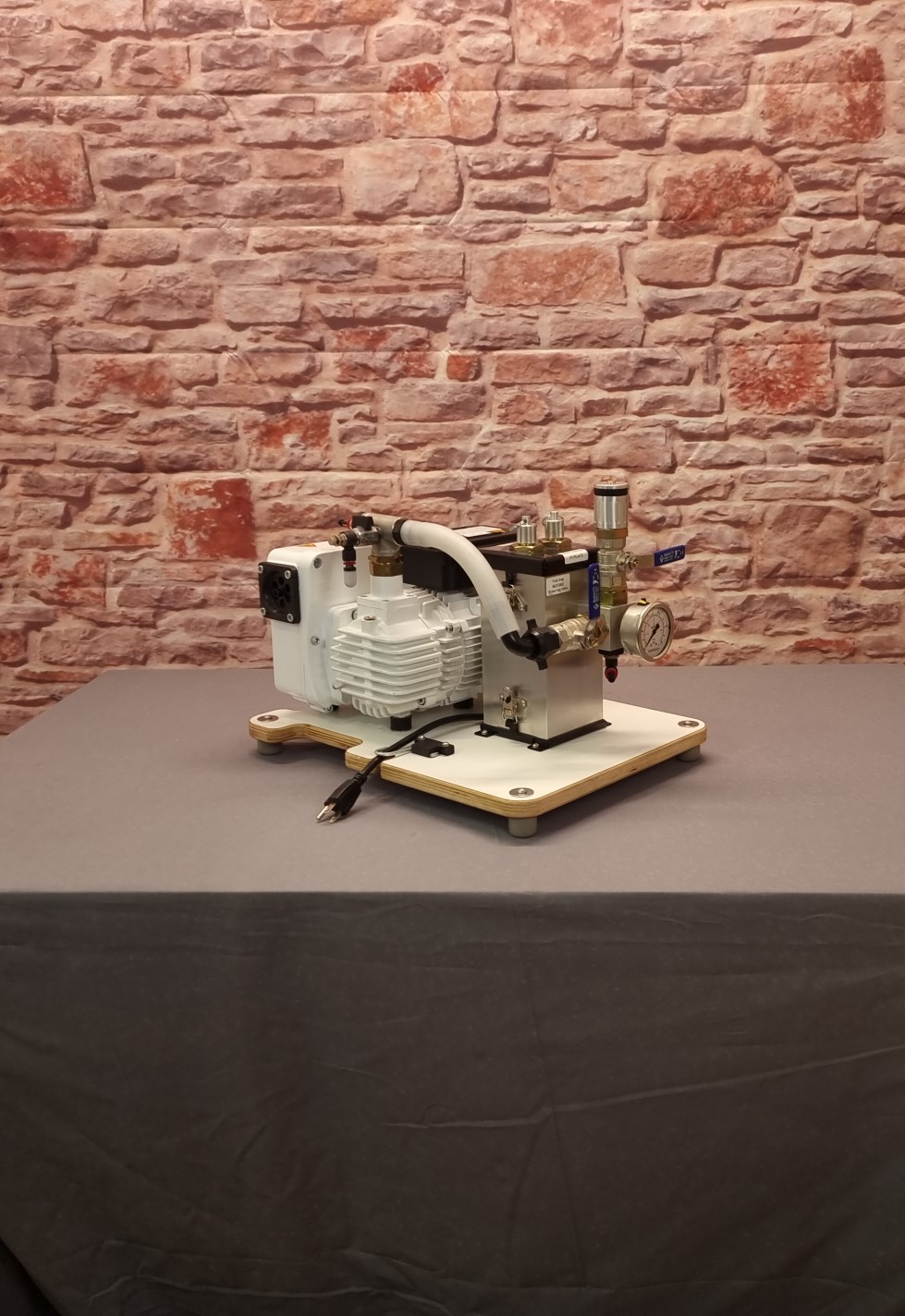

Vacmobiles are extremely versatile in their areas of application, have no installation requirement and are easily relocated. A Vacmobile based plant can quickly be extended in capacity, or even downsized. Vacmobiles deliver the highest manufacturing quality – but without the risk associated with other vacuum solutions.

Vacmobiles simplify vacuum infusion

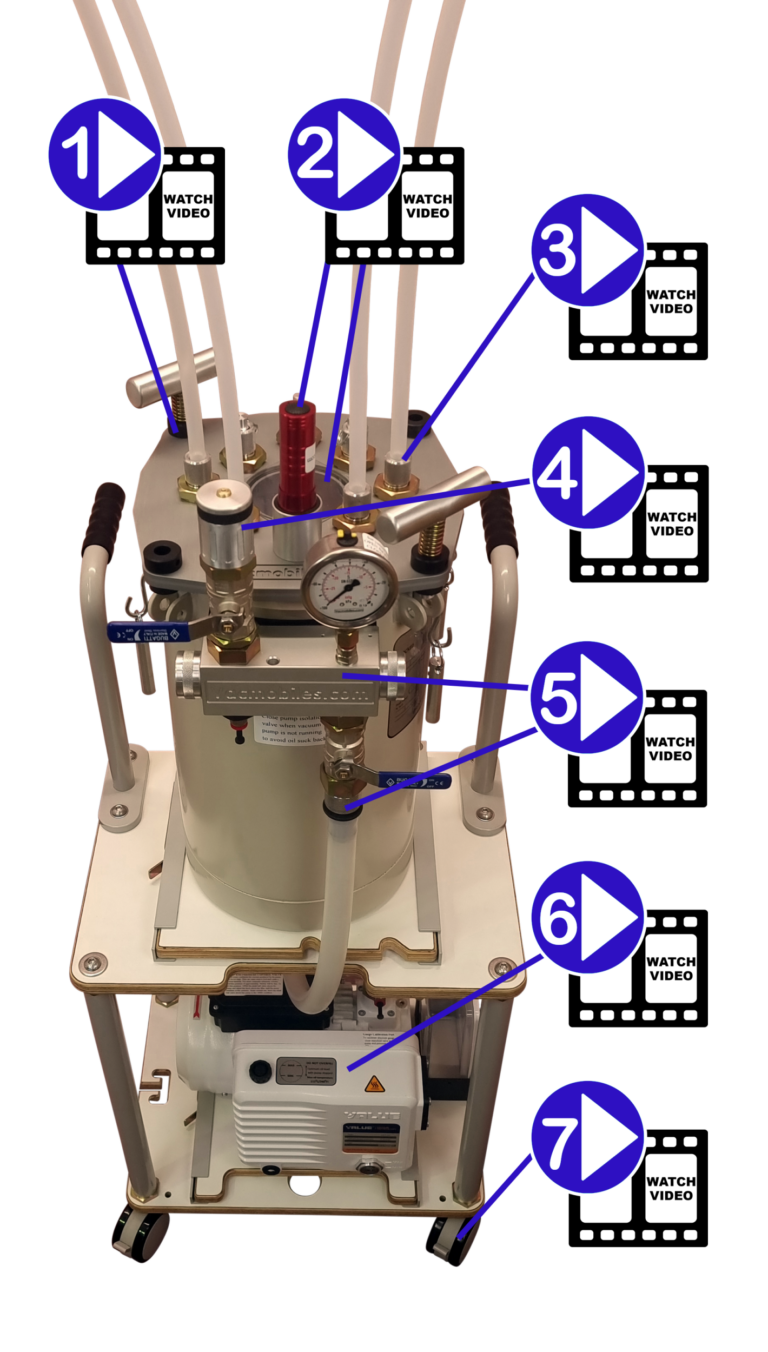

Used by composite manufacturers, researchers & trainers worldwide – click on videos to see why …

- Quickly detachable resin trap lid for easy access to disposable catchpot. Minimal cleaning required.

- Generous 3” (75 mm) diameter viewport with LED illumination to check resin levels. Great for peace of mind when infusing.

- Quick to use, vacuum tight tube connections. Mastic free!

- Vacuum regulation valve. “Must have” with polyester and vinyl ester resins.

- Control valves and vacuum gauge mounted on rugged manifold block. All demountable joints are O-ring sealed. Quick to use and leak tight.

- Minimal service requirements. Easily performed by user.

- Compact & mobile. Use wherever single phase power is available.